Applications

Due to simple design, reliability and with only one moving part i.e., magnetic float, it finds application in various liquids where accurate and repeated liquid level control is called for.

This type of float switches are suitable for centralized lubricating systems for machine tools, printing, packaging, textile and special purpose machines.

Contact Protection Methods

We recommend R-C Network for alternating current circuit and clamping diode for current circuit to protect the contact of float switches.

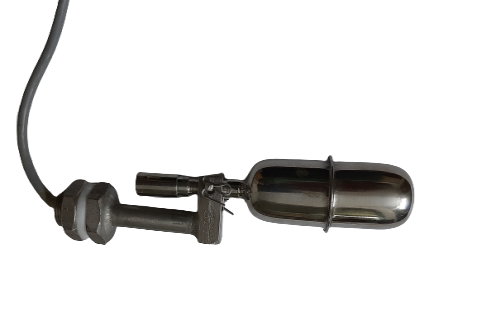

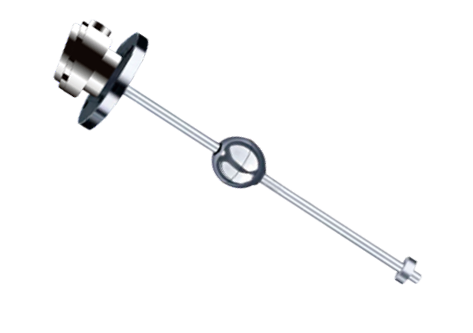

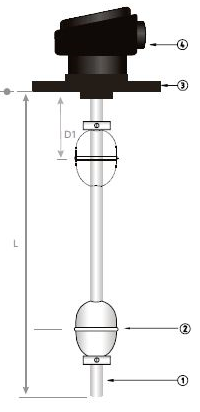

Construction

1 – Stem

2 – Float

3 – Mounting Flange

4 – Enclosure

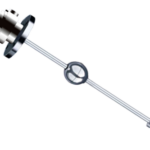

Stem

Non magnetic, non corrosive, SS 316 material for special applications : PP, PVC on request

Float

PU : Polyurethane foam float for temperature up to 80°C & atmospheric pressure. suitable for Water, Oil, Diesel etc.,

SS : SS 316 float for temperature up to 125°C & pressure up to 20Kg./cms2 . Suitable for Water, Oil, Diesel, Chemicals, Solvents, etc,

SP : PP or PVC float for special applications.

Mounting

Level switch comes with either Flanged or Threaded mounting.

Flange

F1 : Φ75mm OD, 60mm PCD, Φ6.6mm 4 mounting holes for PU Foam float

F2 : Φ100mm OD, 80mm PCD, Φ8.8mm 4 mounting holes for SS 316 float

F3 : Std. Table flanges (ANSI, BS, DIN)

F4 : Special (Drawing to be provided by customer)

Threaded

T1 : 1½” BSPM for PU Foam float

T2 : 2″ BSPM for SS 316 float

T3 : Special (Drawing to be provided by customer)

Flange Material

MS : Mild Steel

S1 : SS 304

S2 : SS 316

S3 : Special (consult factory for type of material)

Enclosure

DC : Din solenoid connector made of polyamide suitable for small machine top mountings.

WP : Weatherproof made of cast aluminum enclosure suitable for high temperature, machine top & open environment.

FL : Flameproof made of cast aluminum suitable for group II A & II B zones.

SP : Special enclosures (Drawing to be provided by customer)

Levels

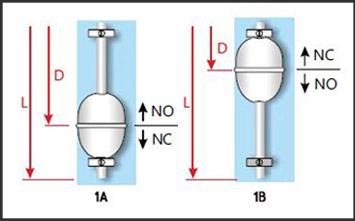

Single Level

Single level switch used for either high level or low level sensing

1A: The contact is normally open when liquid level is above the set level & closes on reaching the set level.

1B : The contact is normally open when ligiid level is below the set level & closes on reaching the set level.

D-Minimum 50mm

L-D+50mm

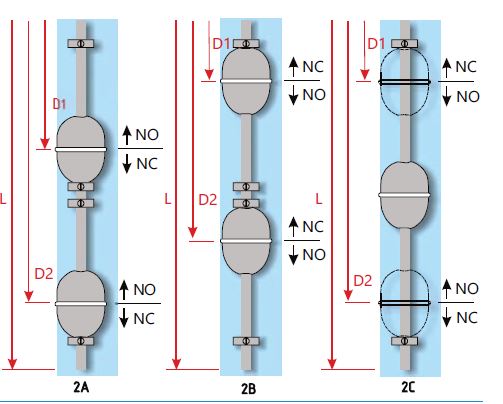

Two Level

Two level switch is used for high & low level sensing.

2A: The contact of both high & low level is normally open when liquid level is above the set level & closes on reaching the respective set levels.

2B: The contact of both high & low level is normally open when liquid level is below the set level and the contact closes when the liquid level reaches the respective set levels.

2C: The contact of both high & low level is normally open. Low level reed contact closes on liquid reaching low level & opens once liquid raises above low level. similarly high level reed contact closes on liquid reaching high level & opens once liquid level falls below high level.

D1-Minimum 50mm

D2-Maximum (L-5O)mm

Minimum distance between D1&D2 75mm

L-D2+50mm

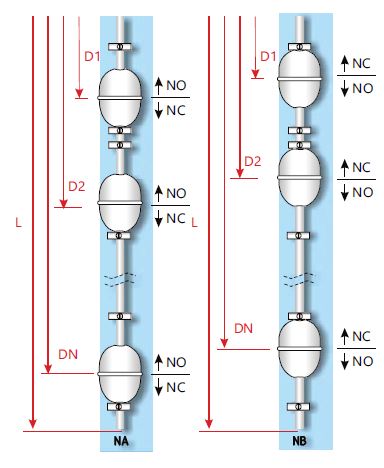

Multiple Level

Multi level switch is used for multiple level sensing.

NA. The contact of all the level is normally open when liquids level is above the respective set level & closes on reaching the set level.

NB : The contact of all the level is normally open when liquids level is below the respective set level & closes on reaching the set level.

Maximum of six set points is possible in a single unit

D1-Minimum 50mm

DN-Maximum (L-50)mm

Minimum distance between each levels-75mn

L-DN+50mm