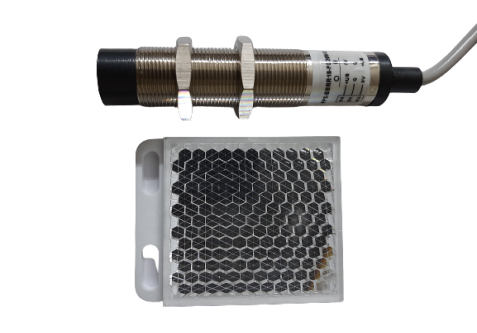

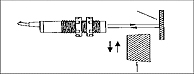

Retroreflective sensors have the light source and the receiver in the same head. The light beam emitted by the source is reflected back to the receiver by a reflector (e.g. triple reflector or reflective foil). Any break in the light path is evaluated by the receiver and in turn results in a change of the output mode.

The reflectivity of the object surface to be sensed effects the sensing distance, so that a correction factor or re-emission factor has to be specified. This value may vary from, less than 10% for matt-black plastic to 200% for raw aluminum sheet metal (special values on request). Usually we recommend an application-dependent test of the specific object to take ambient conditions, such as dust and humidity, into consideration for the selection of the optimum sensor.

Different sensing distances and sensitivity settings are required for different objects (surface, color)